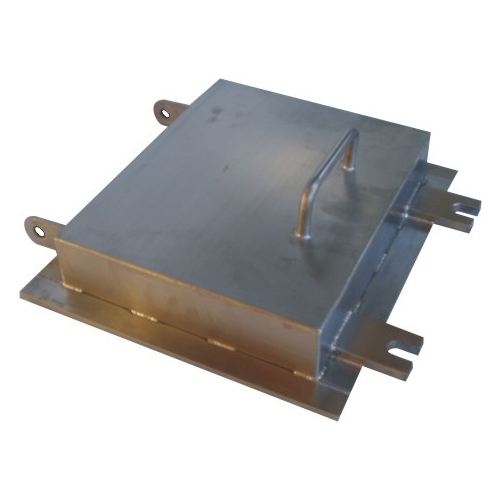

Product Description :

Magnetic Drum Separators are of self-cleaning type and provide continuous removal of ferrous contaminations from a wide range of free-flowing bulk and granular materials in high-volume applications.

BM permanent magnetic drums possess higher strength in comparison of electromagnetic drums. These permanent magnetic drums are made using permanent magnets, which are long lasting in quality and useful for whole of the life. The power of these permanent magnets does not reduce during normal use. Volume of material which can be handled by permanent magnetic drums depends upon the diameter & length of the drum Size Range the larger the diameter and width of the drum the greater is the volume of material which can be handled.

Magnetic Materials : Magnetic separators are offered with two different type of magnets.

Ferrite Magnet : The magnetic separator with ceramic magnet are useful for the application where free and larger iron particles are to be separated. The average magnetic intensity on the magnetic drum surface will be 1500-2000 Gauss.

Rare Earth Magnet : The magnetic separator with high intensity Rare Earth Nd-Fe-B (Neodymium- Iron- Boron) magnets are useful for removing magnetic contamination with low magnetic properties and fine iron particles are to be separated.

The average magnetic intensity on the drum surface will be 3500 – 5500 Gauss. Magnetic drum separator is a self cleaning type system used for separation of Iron in Continuous process line Dry, granular and free flowing material in various industries like: – Refractory – Food – Chemical – Plastic – Glass.

Specifications :

- Application: Construction Usage, Workshop Usage, Container Usage, Mineral Area Usage, Steel Mill

- Sling Type: Cable

- Power Source: Electric

- Type: Double Beam Crane

- Main Girder Form: Double Girder

- Material: Steel

- Size: 4 inches in diameter and 16 inches long

| Model No. | Capacity tones per Hours | Drum Size (Dia mm) | Length mm |

|---|---|---|---|

| BM-771-SDS | 1.5 | 400 | 600 |

| BM-772-SDS | 3.0 | 550 | 550 |

| BM-773-SDS | 7.0 | 650 | 1100 |